There are three key aspects of soapmaking safety: environmental safety, using protective equipment, and handling lye with care. In this blog post, I will explain the importance of creating a safe environment for soapmaking from scratch. Below, I’ve created a video lesson, free downloadable checklist, and a helpful article summary to help set you up for success.

Video lesson

Video transcript

Hi, I’m Priscilla Mensah, and I teach creative souls to make soap from scratch using natural ingredients.

My mission is to honor the traditions of soapmaking and help people experience the transformative power that it holds.

I came up with what I call the 3 S’s of soapmaking, that is safety, supplies, and system.

I’m gonna dive deeper into each of these areas on my channel.

I’m gonna start talking to you about soapmaking safety first.

Safety is my absolute favorite topic!

I was once a Health Safety Environment & Quality manager in a warehouse.

And later on, I spent a lot of time working in insurance risk control as a consultant.

And I got the opportunity to talk about environmental safety and health all day long and it was a lot of fun.

I remember back when I was a safety manager in the warehouse, there was a large poster on the inside, just above

the entrance, and it said “Safety is our 1st priority.”

Beneath it, we had a sign that numerically read out the number of days that had passed by without an accident in the warehouse.

I was safety manager there as a trainee, and it was so easy for me to take safety seriously because what it meant was

that every worker could come in, they could do their job, and then they could leave and go home safely to their families.

And my attitude towards safety is no different as a soap maker.

And that is really why I wanna talk you about soapmaking safety today.

One of the main things that people who take my in person classes want to know is how do I safely make soap?

And I hear you! The main things you wanna think about are working in the proper environment, using non-negotiable

personal protective equipment called PPE.

And also understanding the role of sodium hydroxide, also known as lye, when you’re making soap, and how to handle it

with care through the process.

So soapmaking safety is about 3 things: environmental safety, using protective equipment and handling lye with care.

Most of this is intuitive, and it’s also worth repeating as well.

I hear from people in my live classes all the time about their fear of handling lye.

And to be honest, it’s the reason why I took in-person soapmaking classes. I wanted to see somebody handle this

and know exactly what I was getting into before taking the reigns and doing it on my own.

Fear of working with lye prevents people from ever attempting to make soap. But not you! Okay!

If you’re watching this video, that means you’re here to learn common sense tips on handling this with care.

Remember, lye deserves your respect. It’s not something to fear.

Now, in this video, we’re gonna zoom in and talk about environmental safety first.

So before you even begin soapmaking, you need to prepare your environment.

What does that mean? Well, I wanna make it clear that you can make soap pretty much anywhere.

I’ve made soap in my kitchen. I’ve made soap in an office environment that had a kitchen within it.

I’ve made soap in a hotel conference room. I’ve made soap at the George R Brown Convention Center.

At a large event. And I’ve made soap outside in the open air.

What matters is that your environment has plenty of ventilation.

It’s an environment that you can communicate very clearly to everyone who is around what you’re working on.

And it’s also a space that allows you to lay things out

nice and organized without having to worry about anybody moving anything.

No matter where you are in the world, what matters most is that you have plenty of ventilation.

And it’s key when making soap because you’re dealing with chemicals that are harmful to the body when they’re inhaled.

I teach live classes in offices with a kitchen and access to fresh open air.

And at home, it’s pretty much the same. The kitchen area is where I make soap.

And I have access to the outdoors for mixing the lye and the water and allowing that to dissipate out in the open air and

not in a confined space.

And remember, it doesn’t have to be your kitchen.

You can do this in the bath room, in your garage, a convention center, barn, hotel room, all kinds of places where

you can make so.

What is key is having ventilation.

You can do this in a science lab as long as there is a hooded vent above while you’re working.

Next is communication, when we’re talking about this step of what you’re doing before you even make soap.

Communication in your environment is key. To the other adults of the house, tell them.

“Hey, I’m making soap. Don’t come through here until I say it’s all clear.”

You wanna tell everyone around what you’re up to.

And then you’re also gonna need to be in a place that’s free of distractions.

So you don’t wanna be in a place where you have, you know, your pets running around, where you’ve got kids playing, and

one that can stumble into your workspace or distract you.

Now that I’m a mom, I ask for help watching the babies while I make soap.

Or ah, hey, I’m just gonna make soap while they’re snoozing, taking a nap, or at night when they’re asleep.

And you also want to be in a workspace where you can lay everything out that you need and get to it relatively easy.

So what I mean by this is first, you’re gonna wanna make sure that your soap and your supplies, your soapmaking

supplies are gonna be in a closed cabinet, ideally in a locked room or in a place where no one can really get to your

soapmaking materials.

Um, you’re gonna make sure that in that space, things are clearly labeled so that anyone who does get into your storage

space, they understand what it is, they know what oils are present, they know what the lye looks like and it’s properly

labeled, and they’ll know that, Hey, this should not be a bottle that’s just opened

willy nilly. Um, all of that is super important.

So ensuring that your workspace is nice and clear.

Everything is laid out easily so you can get to it when you are not using materials, having things labeled and put away in

cabinets in a nice cool space.

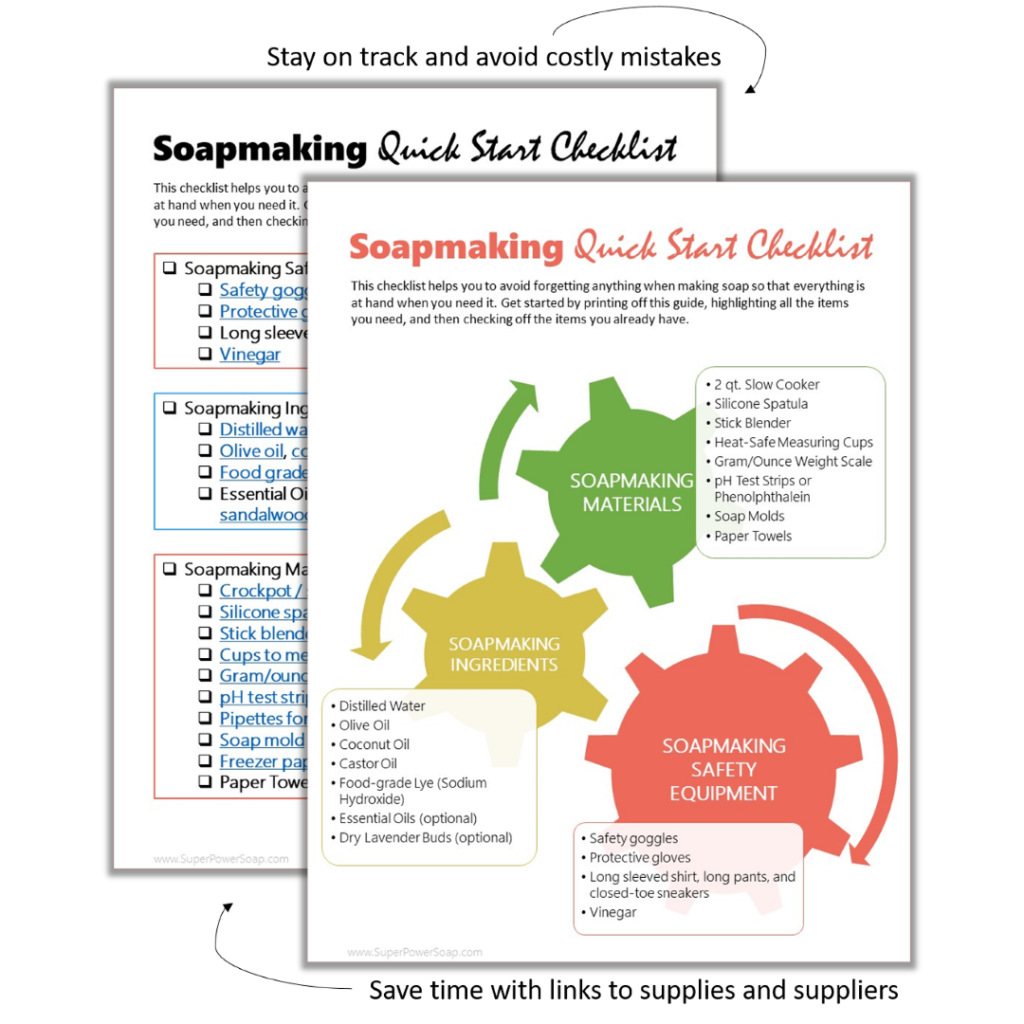

Wonderful. And also while you’re soap making, whether it’s your first time or if it’s your 100th time making soap, you’re

likely following a written recipe or a video.

And so if that’s the case, you want to have your phone, your computer, or that printed recipe, in a super easy to read spot

so that you’re not moving all around.

Tryin’ to “Oh! Let me make sure I got everything I need.”

Um, I keep my soapmaking checklist right front and center, and I have my recipe next to it every time I make soap, just so

I’m keeping track of what’s going on.

Because when things start moving, they start moving fast and getting things organized in your environment is key to keeping

up with that whole process.

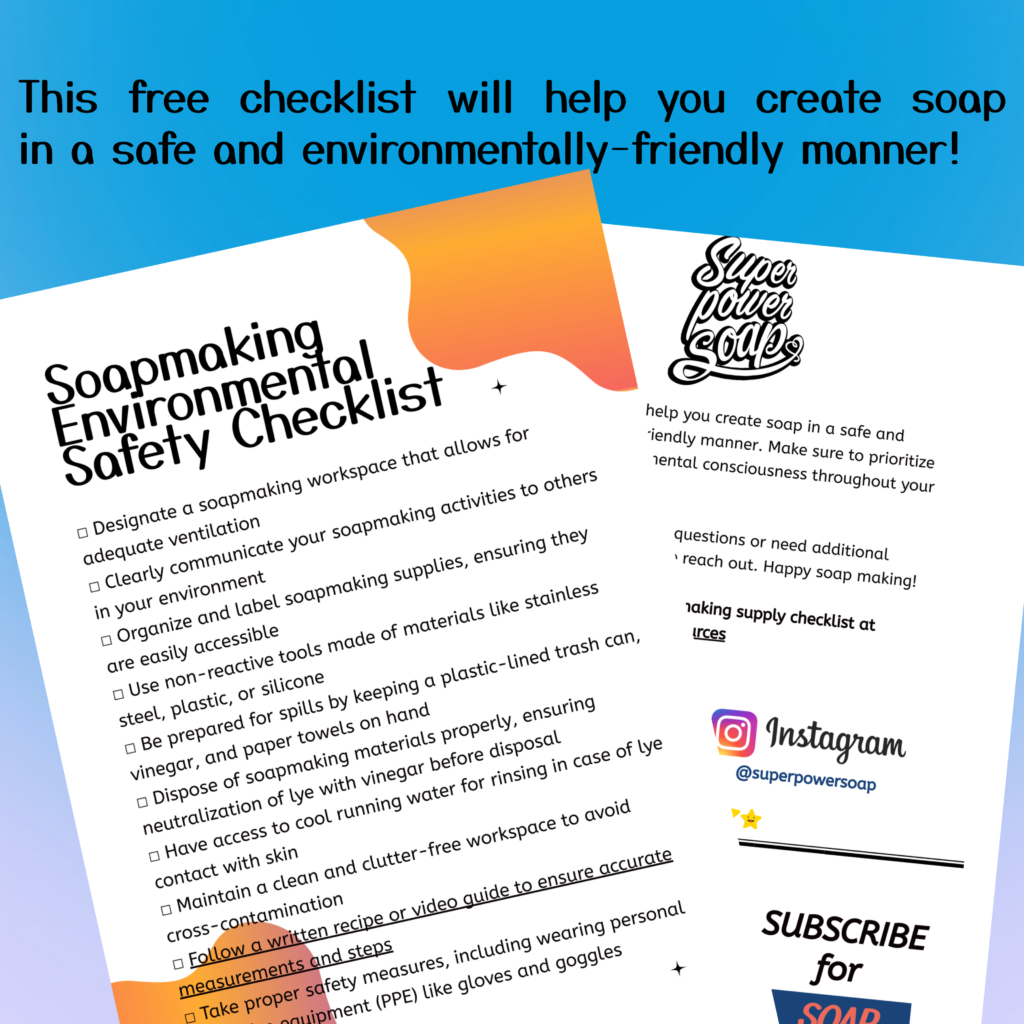

So during soapmaking, once you actually start getting into it, environmental safety is still super important.

So we talked about getting everything laid out neatly so that you can just have access to it when you need it, but it’s so

important to have things organized so that you can avoid cross-contamination once you get into the making.

Environmental safety also includes using heat-resistant non-reactive tools when you’re making soap.

This means no glass, no aluminum. None of that. You’re gonna opt for stainless steel, plastic, and silicone.

Now I’m gonna say accidents while making soap are highly unlikely, especially if you’re taking these kinds of common

sense approaches to making soap.

But despite the fact that they’re unlikely, you still wanna be prepared for spills in your environment.

And it’s critical to always be ready for that to happen.

For this you’re gonna want to make sure you’ve got a plastic lined trash can, vinegar on hand, so you can pour them over

lye spills on any surfaces and access to cool running water on the rare occasion that lye spills on skin you’re gonna want to

run your skin under cold water.

After soapmaking it’s also important to protect your environment.

Arguably, one of the most important parts of protecting your environment is after you make soap.

And a lot of soapmakers don’t talk about what they do after the process of making it, but I want you to be aware that

environmental safety is key here.

You are working with lots of different chemicals. Different butters, fats, and lye

And environmental safety means that you’re disposing of all of this.

Environmental safety means that you’re disposing of all of this

well, and that means that you’re using that vinegar to rinse over any lye-soaked tools, that you are diluting those tools

with water after you’ve rinsed them with vinegar to neutralize that reaction in your area with newspaper, with butcher paper,

that you have extra paper towels on hand so that you can wipe down pots and pans that you’re using.

Why? So this way you don’t clog your pipes.

The last thing you wanna do is put a bunch of oil and butter and materials down your drain.

You’ll have some issues. In addition, you wanna make sure that when you’re disposing of things, you’re ensuring that your

lye is neutralized before any of it goes into the trash.

And you’re also ensuring that there is no aluminum in the area whatsoever when you’re working with lye, or even if

you’re disposing something that has lye on it, throw it into the trash, you don’t want aluminum foil to be right underneath it.

You’ll actually cause a super noxious reaction. Something to certainly be aware of.

So, have a plan on what you’re gonna do before you start making soap and how you’re going to dispose of everything.

Now.

I mentioned working in a space where you’ll have access to a sink with running water.

And you’re gonna need this after soap making too.

Once your materials are neutralized and you wipe down all, the excess product that you’ve disposed of that, you’ll want

warm soapy water to wash everything and allow that to go down the drain once you’ve taken the majority of it off.

I wanna also say you should never dispose of lye in a place where it can seep into the ground or natural bodies of water.

Okay. So environment is all about securing the area before you start, having all of your supplies and materials easy to

access when you’re making soap, and having a clear plan for how you’re gonna dispose of stuff once it’s all said and done.

Environmental safety is key. So to recap, soapmaking safety is about environmental safety, using protective equipment,

and handling lye with care.

Most of this is intuitive and it’s worth repeating.

This video focused on environmental safety, and in

the next videos, we’ll talk about protective equipment and handling lye specifically.

Remember, putting safety first means that everyone can come in, do their work, make their soap, go home, and enjoy

time with your families.

And in the soapmaking making context, it’s the same thing.

Proper preparation, helps you have soapmaking success. Alright. So thank you for listening.

Again, I’m Priscilla, founder of Super Power Soap, where I’m here to not only share the wonderful techniques of

soapmaking, but to also preserve this wonderful craft, to honor my family traditions and legacy and to help you

understand the transformative effects and impact of soapmaking in your own life.

Thank you.

And if you have any questions or comments include them below, and let’s talk.

Environmental safety before soapmaking

Choose a clear workspace

Before embarking on the soapmaking process, it is crucial to prepare a suitable environment. While soap can be made almost anywhere, ventilation is of utmost importance. Chemicals used in soapmaking can be harmful when inhaled, so ensuring ample airflow is crucial. Communicate with those around you and ask them to avoid the soapmaking area during the process. Setting up a space free from distractions and ensuring all supplies are organized and easily accessible are also essential.

Environmental safety during soapmaking

Tools and Equipment

Using the right tools and equipment is key to maintaining soapmaking safety. When working with lye, a caustic substance, it is important to have proper personal protective equipment (PPE) such as gloves, safety goggles, and aprons. Use heat-resistant, non-reactive tools like stainless steel, plastic, and silicone. Glass and aluminum can cause unwanted reactions. Prepare for spills by having a plastic-lined trash can, vinegar, and access to cool running water is also crucial.

Environmental safety after soapmaking

Proper Disposal and Post-Soapmaking Safety

After you have successfully made soap, it is equally important to protect the environment by disposing of materials properly. Use vinegar to rinse any lye-soaked tools and dilute them with water to neutralize the reaction. Clean up all excess product and dispose of it without clogging drains or causing harm to the environment. Having a clear plan for disposal and ensuring lye is neutralized before throwing anything away is essential.

Maintaining soapmaking safety is vital for both personal well-being and environmental protection. By focusing on environmental safety, using the appropriate tools and equipment, and understanding proper disposal methods, we can enjoy the transformative effects of creating soap from scratch.

Ready to make your own luxurious soap? Join my online course Simple Soapmaking for Sensitive Skin.